Static Control Products

Static electricity can discharge via an arc or spark when plastic material comes in contact with another body of a sufficiently different potential, such as a person or a microcircuit. When this electrostatic discharge (ESD) occurs, some electronic parts can be destroyed or damaged, resulting in equipment downtime, costly repair or total part replacement. ESD is also dangerous in an environment containing flammable liquids, solids or gases, such as in a hospital operating room or during the assembly of explosive devices.

Static electricity can discharge via an arc or spark when plastic material comes in contact with another body of a sufficiently different potential, such as a person or a microcircuit. When this electrostatic discharge (ESD) occurs, some electronic parts can be destroyed or damaged, resulting in equipment downtime, costly repair or total part replacement. ESD is also dangerous in an environment containing flammable liquids, solids or gases, such as in a hospital operating room or during the assembly of explosive devices.Virtually all PCC products are now available in one or more conductive materials to protect against ESD damage. The following tables give the nominal physical characteristics of each of our conductive materi als. This information has been provided by the suppliers and, as such, is not warranted by PCC.

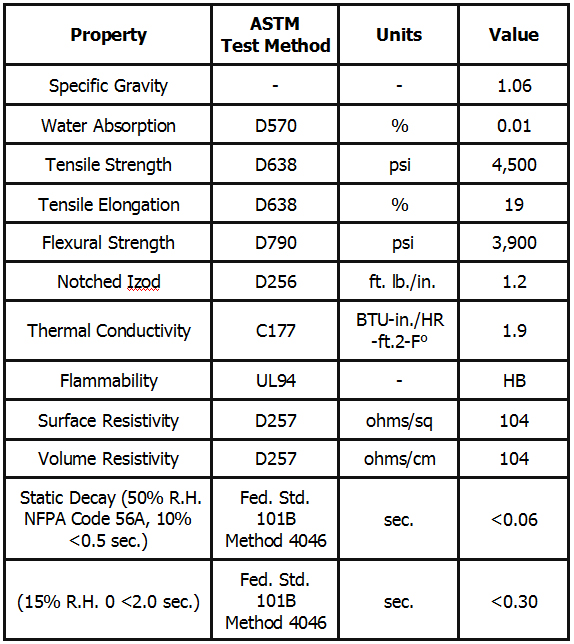

CONDUCTIVE ABS PLASTIC

(Price Guide Abbreviation: B)

Electrically conductive ABS materials are i ntended for applications where dissipation of electro-static charge is required. Conductive ABS is permanently conductive and exceeds the mandatory static decay time required for static-sensitive electrical devices as defined in Military Standard MIL-B-81705B, Method 4046, Federal Test Method 101B. This material contains no halogens and is currently available only in black.

ntended for applications where dissipation of electro-static charge is required. Conductive ABS is permanently conductive and exceeds the mandatory static decay time required for static-sensitive electrical devices as defined in Military Standard MIL-B-81705B, Method 4046, Federal Test Method 101B. This material contains no halogens and is currently available only in black.

ntended for applications where dissipation of electro-static charge is required. Conductive ABS is permanently conductive and exceeds the mandatory static decay time required for static-sensitive electrical devices as defined in Military Standard MIL-B-81705B, Method 4046, Federal Test Method 101B. This material contains no halogens and is currently available only in black.

ntended for applications where dissipation of electro-static charge is required. Conductive ABS is permanently conductive and exceeds the mandatory static decay time required for static-sensitive electrical devices as defined in Military Standard MIL-B-81705B, Method 4046, Federal Test Method 101B. This material contains no halogens and is currently available only in black.STATIC DISSIPATIVE PLASTIC

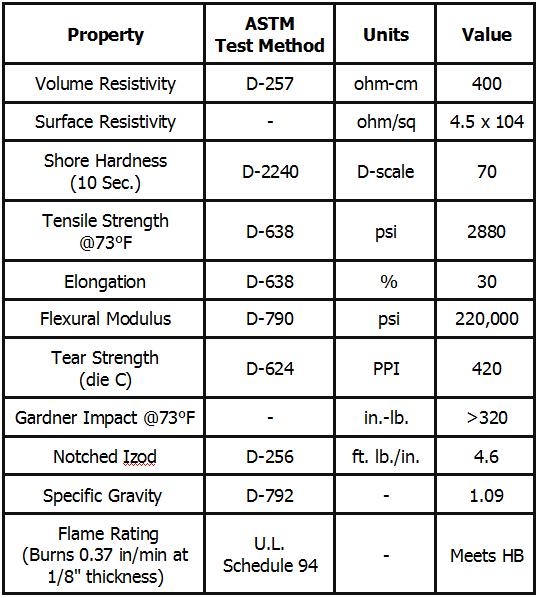

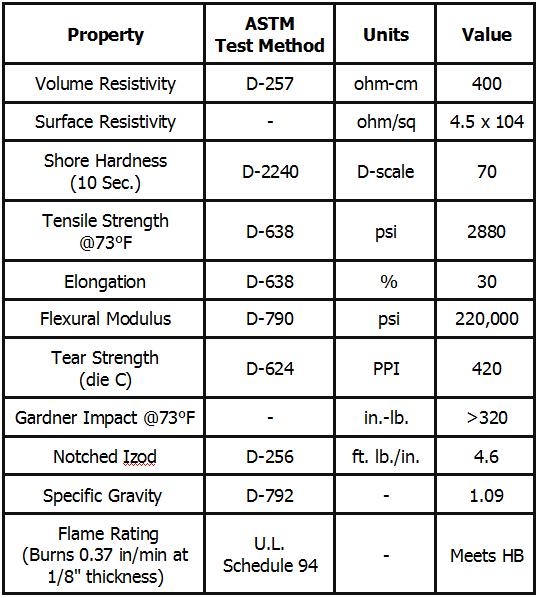

(Price Guide Abbreviation: D)

PCC products formed of this material exhibit high impact strength. The material is non-corrosive and non-crayoning. Static dissipative plastic is non sparking and in compliance with MIL-B-81705B static decay requirements. Totes and boxes formed of this material provide the dimensional stability required for robotic material handling systems, among myriad other uses.

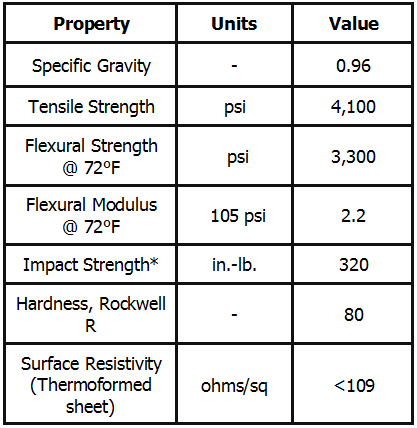

*Gardner Drop Weight-Minimum Value

*Gardner Drop Weight-Minimum Value